If you drive an L5P Duramax and care about real performance not brochure numbers the L5P downpipe deserves more attention than it gets. It’s not flashy. It doesn’t scream for attention. But it sits at one of the most critical choke points in the entire exhaust system, quietly deciding how efficiently your turbo can do its job.

I’ve seen plenty of builds where owners throw money at tuning, intakes, or exhaust tips while leaving the factory downpipe untouched. That’s like opening the front door but keeping the hallway blocked. You might move more air, but it still bottlenecks where it matters most. The L5P downpipe fixes that problem at the source.

This article breaks down what an L5P downpipe actually does, why the factory unit holds the truck back, and how the right upgrade can change how your Duramax drives, pulls, and responds especially in off-road and heavy-use scenarios.

Understanding the L5P Exhaust System Layout

The L5P Duramax exhaust system was engineered to meet emissions standards first. Performance came second. That’s not a criticism; it’s reality. From the turbocharger outlet, exhaust gases flow into the downpipe, then through emissions components, and finally out the tail end. The downpipe is the very first section after the turbo. Whatever happens here affects everything downstream.

Wikipedia’s overview of an exhaust system explains how restrictive routing increases exhaust backpressure, especially near the turbocharger, where pressure buildup most directly impacts efficiency and response.

On the L5P platform, this area is extremely tight. GM had to route the factory downpipe through cramped engine bay real estate while controlling heat and emissions. The result is a pipe with sharp bends, reduced diameter sections, and compromises that make sense for compliance but not for performance. Compared to earlier Duramax generations, the L5P’s factory downpipe is more restrictive right out of the turbo. That’s why upgrading the L5P downpipe often delivers more noticeable real-world gains than people expect.

What Is an L5P Downpipe?

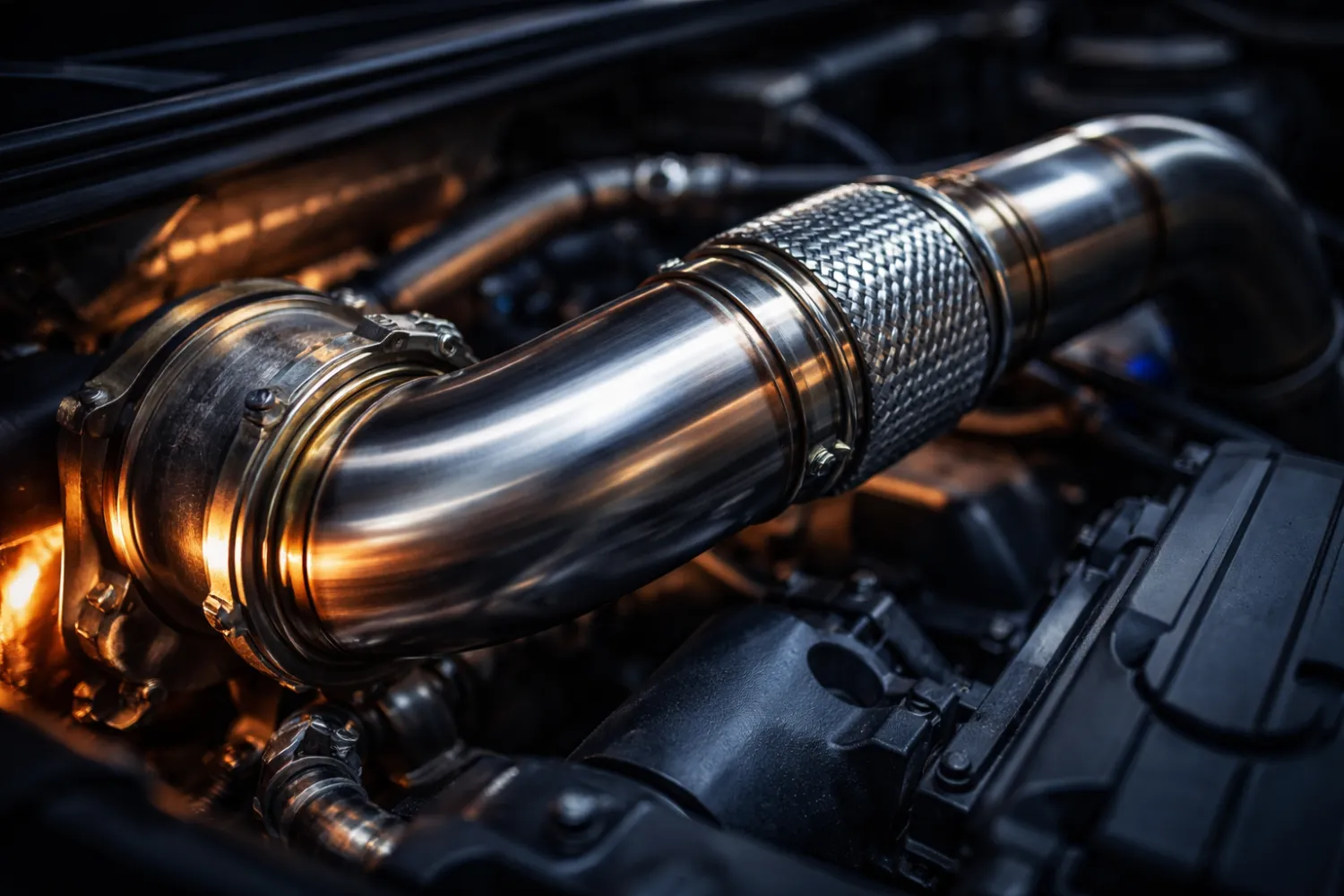

An L5P downpipe connects the turbocharger to the rest of the exhaust system. Its job is simple: move hot exhaust gases away from the turbine as smoothly and quickly as possible.

Design determines whether it succeeds. A properly engineered downpipe improves exhaust velocity, reduces turbulence, and lowers backpressure right where the turbo needs relief. That directly affects spool time, throttle response, and exhaust gas temperature behavior.

The factory downpipe works. It just works under constraint. That inefficiency shows up as delayed boost response, faster EGT rise under load, and unnecessary stress on the turbocharger itself.

Where the Factory L5P Downpipe Falls Short

The stock L5P downpipe isn’t “bad.” It’s just limited by its priorities.

Key restrictions include:

- Tight, non-mandrel bends that disrupt flow

- Reduced internal diameter near the turbo outlet

- Heat retention caused by airflow turbulence

- Increased backpressure under sustained load

Under light driving, you might never notice. Under towing, climbing, or tuned conditions, it becomes obvious. Backpressure rises. Heat builds faster. Turbo response softens when you want it sharp.

That’s exactly the kind of inefficiency performance-focused owners want gone.

Performance Benefits of an Upgraded L5P Downpipe

This is where the L5P downpipe earns its reputation.

An upgraded unit doesn’t just add power. It changes how the truck behaves in everyday use.

Real-world benefits include:

- Faster turbo spool

- Smoother throttle response

- Lower EGTs under sustained load

- Reduced stress on turbo components

- More consistent power delivery

Wikipedia’s exhaust system documentation highlights how reducing backpressure upstream of the turbo improves overall engine efficiency, especially in forced-induction applications. That theory shows up clearly in real-world L5P driving.

Most drivers feel responsiveness first. The truck stops feeling hesitant. Boost builds earlier. Power delivery smooths out instead of arriving all at once. Peak horsepower numbers may not skyrocket, but drivability improves everywhere and that’s where real value lives.

Materials and Build Quality: Where Problems Start or End

Material choice matters more than marketing claims.

Common downpipe materials:

| Material | Advantages | Drawbacks |

| Aluminized Steel | Lower cost | Susceptible to corrosion |

| T304 Stainless Steel | Excellent heat resistance, longevity | Higher upfront cost |

Mandrel bends are essential. Crush bends defeat the purpose by reintroducing restriction. High-quality welds, thick flanges, and a properly designed flex section all matter. Cheap construction leads to cracked welds, warped flanges, and leaks especially with repeated heat cycling. This component lives inches from the turbo. Build quality isn’t optional.

L5P Downpipe Diameter: Bigger Isn’t Always Better

More diameter doesn’t automatically mean more performance.

Most L5P setups perform best with a 3.0-inch or 3.5-inch L5P downpipe, depending on the rest of the build. Going too large too early can reduce exhaust velocity, which slows spool on stock or mildly upgraded turbos.

Practical guidelines:

- Stock turbo, light tuning: 3.0″

- Tuned towing builds: 3.5″

- Large turbo setups: size based on airflow goals

Balance beats bragging rights every time.

Downpipe Compatibility With Delete Kits and Exhaust Systems (Off-Road Use Only)

On off-road builds, the L5P downpipe becomes even more important.

Once emissions components are removed, the downpipe dictates how smoothly exhaust transitions into the rest of the system. Poor fitment here causes leaks, vibrations, and premature failure.

Key compatibility checks:

- Correct turbo flange angle

- Clearance at firewall and transmission

- Smooth transition into mid-pipe

- Adequate flex section length

Fitment problems aren’t minor annoyances. They become long-term reliability issues.

Installation Overview: What to Expect

Installing an L5P downpipe isn’t beginner-level work, but it’s manageable with patience.

Expect:

- Tight engine bay access

- Heat shield removal

- Careful routing past the firewall

- Precise flange alignment

Most shops complete the job in 3–5 hours. DIY installs take longer, especially the first time. Rushing the install is the fastest way to create leaks or vibration problems later.

Tuning After an L5P Downpipe Upgrade

A downpipe improves flow. Tuning teaches the engine how to use it. Improved exhaust flow changes turbo behavior, boost onset, and heat characteristics. Proper tuning accounts for those changes with refined fueling and boost control. Even conservative off-road tuning dramatically improves how the L5P downpipe upgrade feels behind the wheel.

Supporting Mods That Maximize L5P Downpipe Gains

A downpipe works best as part of a balanced system.

Supporting upgrades include:

- High-flow intake with proper filtration

- Free-flowing exhaust system

- Intercooler upgrades for sustained load

- Turbo upgrades when power goals increase

Each mod amplifies the others. None should be treated as a standalone fix.

Who Benefits Most From an L5P Downpipe?

This upgrade shines in real working conditions.

Best candidates:

- Trucks that tow heavy

- Off-road builds under sustained load

- Tuned daily drivers

- Owners planning future turbo upgrades

For lightly driven stock trucks, gains may feel subtle. For trucks that work, the improvement is undeniable.

Heat, Emissions Engineering, and Why Flow Matters

Factory exhaust design prioritizes emissions control and heat management. According to the U.S. Environmental Protection Agency, exhaust temperature and flow directly affect engine efficiency and component longevity in heavy-duty diesel applications.

Restricted exhaust flow raises heat and pressure near the turbocharger. By improving flow immediately after the turbine, an aftermarket L5P downpipe helps manage thermal load more effectively during towing, off-road driving, and long pulls. Lower heat isn’t just about performance. It’s about durability.

Common Myths About L5P Downpipes

“You won’t feel a difference.”

You will, especially under load.

“Only high-horsepower builds need one.”

False. Stock turbos benefit too.

“All downpipes are the same.”

Material, bends, and fitment make a massive difference.

Longevity, Maintenance, and Reliability

A quality L5P downpipe reduces turbo stress, improves heat control, and lasts longer especially when built from stainless steel.

Maintenance is simple:

- Periodic leak checks

- Visual inspection of welds

- Verify flange torque after heat cycles

Install it correctly once. Enjoy the benefits for years.

Legal and Off-Road Use Disclaimer

Performance exhaust modifications are intended for off-road use only. Emissions regulations vary by location, and owners are responsible for compliance with local laws.

Explosive Diesels provides performance education, not legal guidance.

Final Thoughts: Is an L5P Downpipe Worth It?

Yes if you care about how your truck actually performs. The L5P downpipe doesn’t scream for attention. It quietly removes one of the biggest factory restrictions holding the platform back.

Better response. Lower heat. Smoother power. Less stress. That’s real performance. And for trucks built to work hard, it’s one of the smartest upgrades you can make.

FAQs

An L5P downpipe improves exhaust flow directly after the turbocharger, reducing backpressure and helping the turbo operate more efficiently.

It can support horsepower gains, but most drivers notice faster turbo response and smoother power delivery rather than big peak numbers.

Yes, especially under load, where improved throttle response and reduced heat buildup become more noticeable.

Tuning is not required, but proper tuning helps unlock the full benefit of improved exhaust flow.

Yes, better exhaust flow reduces backpressure, which helps control EGTs during towing and sustained driving.

T304 stainless steel offers the best durability and heat resistance for long-term performance.

Yes, an L5P downpipe can be installed on its own and still deliver noticeable improvements.

Installation requires working in tight spaces and is best handled by experienced DIYers or professional shops.

Towing trucks, off-road builds, and tuned daily drivers see the most noticeable performance gains.

Exhaust modifications are often intended for off-road use only, and legality depends on local emissions regulations.